Welded Plate Heat Exchangers Manufacturers

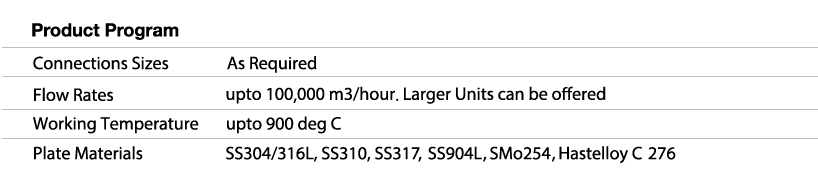

VARALKA Welded Plate Heat Exchangers are light and compact and offer efficient heat transfer for a wide range of clean and dirty process duties. Hence these are now becoming first choice of process engineers for heating, cooling, condensation and evaporation of water, steam, gases vapours, and hydrocarbons, amines, glycols, etc.

Varalka welded heat exchangers are made with thin and efficient heat transfer plates in different sizes, shapes, thicknesses, and corrugations. Baffles can be installed to enable a multi-pass design or modular design for high flow rates. As there is no gasket, there are no restrictions due to gasket materials.

These heat exchangers support high temperatures (upto 1000 ˚C) and large flow rates. Modules can be removed for easy mechanical cleaning. Small hold up volumes allow quick response time, fast cleaning, and hence high productivity.

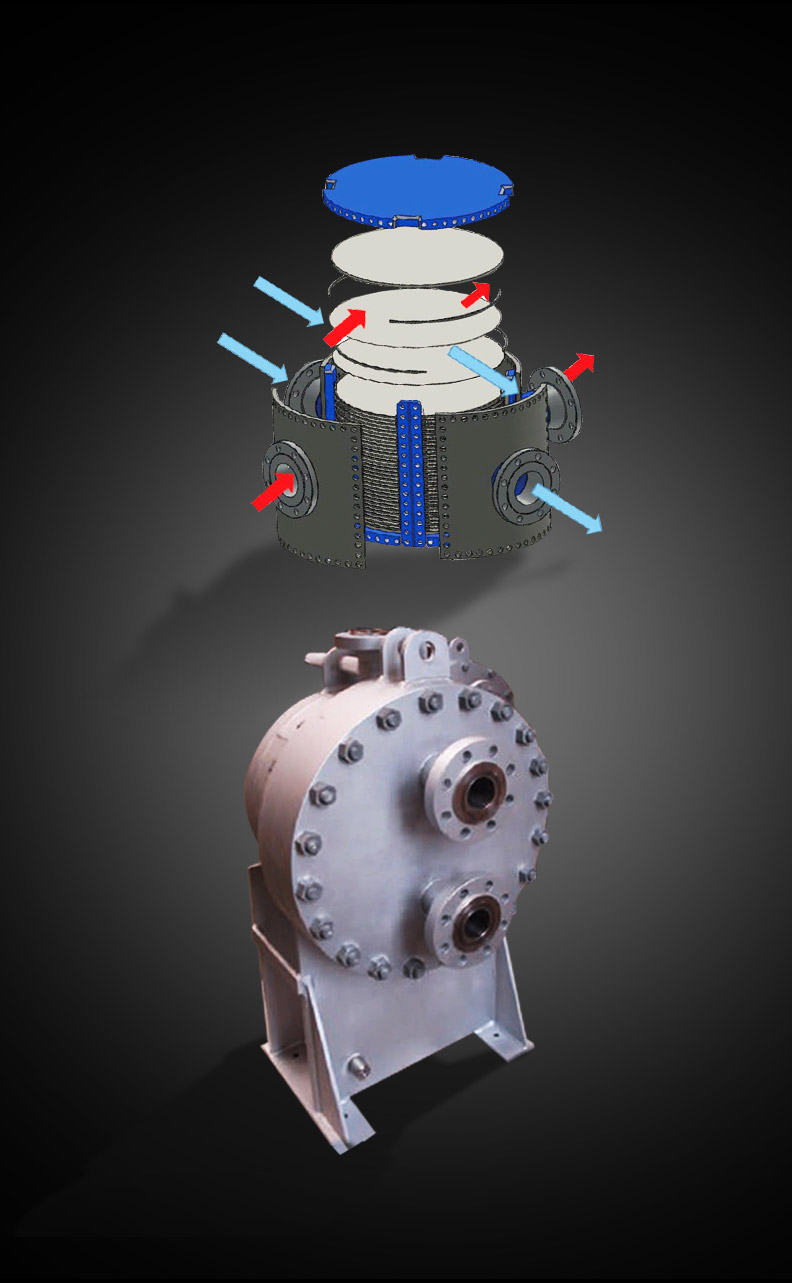

Shell and Plate Heat Exchanger

Varalka Shell and Plate Heat Exchanger is a solution for a demanding working environment requiring high efficiency in a compact size. These welded heat exchangers combine the merits of shell and tube heat exchanger with advantages of conventional plate heat exchangers, The Plate and Shell Heat Exchanger consists of corrugated circular metal plates that are welded together and installed into a pressure vessel to provide high heat transfer.

The Plate and Shell Heat Exchanger consists of corrugated circular metal plates that are welded together and installed into a pressure vessel to provide high heat transfer.

- Fully welded construction, very strong mechanically. Can handle thermal shocks

- Wide range of metallurgies – SS304, SS316L, SMo254, Hastelloy C-276, Titanium

- Compact Size and Light Weight

- Flexible orientation, vertical and horizontal

- Wide temperature range (-60˚C to +450 ˚C )

- Design pressures upto 100 bar

- Can be manufactured to ASME Sec VIII, PD5500

- PED 97/23/EC, CE Marking available

- Gasket Free.. so can be used where gasket was a limitation

- Removable plate pack option available allowing easy access for cleaning

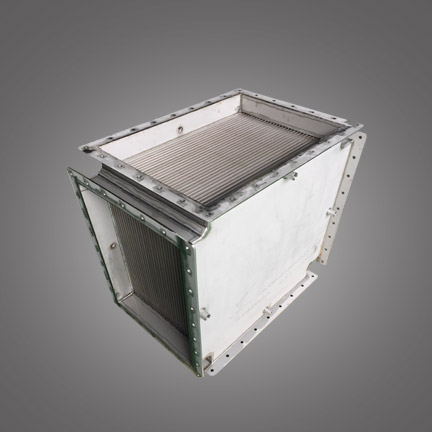

Gas to Gas and Gas to Liquid Heat Exchangers

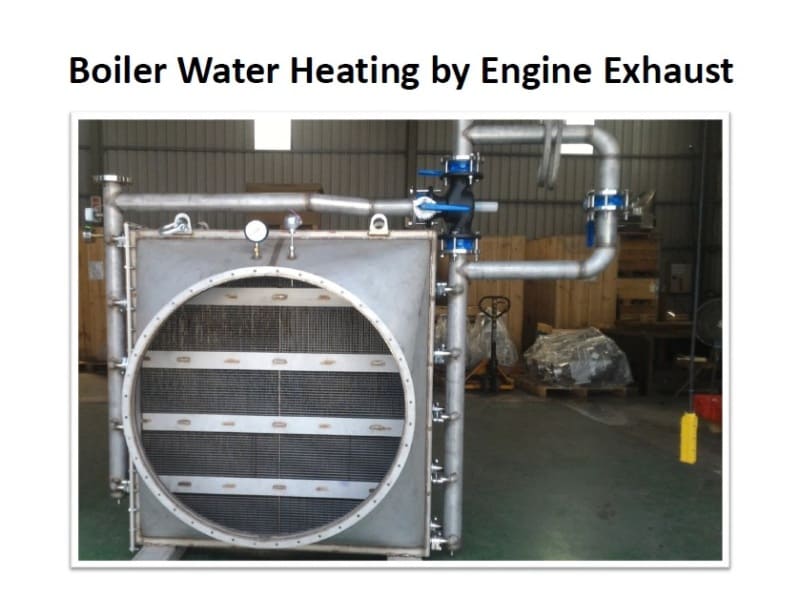

Heat Recovery and Solvents Recovery are useful tool in productivity improvements in industries worldwide. Equipment to recover waste heat or solvents help in sustainable development as well as increased efficiency of processes.

Varalka welded heat exchangers can be used for Exhaust Gas Heat Recovery, Waste Heat Recovery Heat Exchangers and Solvent Recovery. These are all metal construction with plates welded to each other by laser welding. These heat exchangers can be used to transfer heat from Gas to Gas or from Gas to Liquid.

Applications

Welded Plate Heat Exchangers can be used for Single Phase and Two Phase Duties for

- Oil and Gas Production – Onshore and Offshore

- Refineries and Petrochemical Plants

- Nuclear Industry

- Heating and Cooling

- Condensation and Evaporation

- Heat Recovery